Description

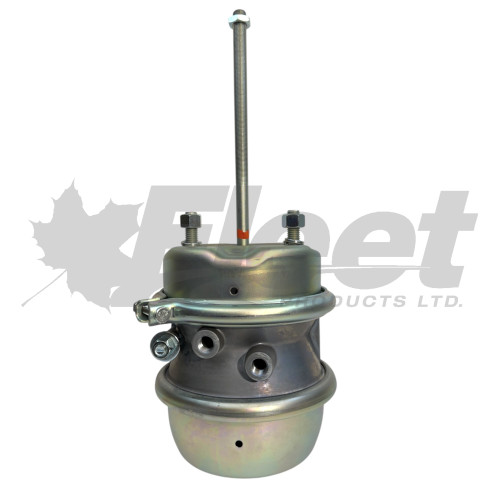

SB3030S2500 - 30/30 STD SPRING BRAKE

PART NUMBER(S):

Fleet Products: SB3030S2500 | OE: 1010447, 1010449, S2500 | Automann: 170.3030S2500

DESCRIPTION:

Model: 30/30 Standard Stroke Spring Brake Chamber

Vehicles: Freightliner, Kenworth T660, Peterbilt 379, Volvo VNL 670 Gen 2 (2003–2019), and other heavy-duty trucks/trailers

• Chamber Size: 30/30 (30 sq. in. service, 30 sq. in. emergency)

• Stroke: 2.5" standard stroke

• Push Rod Length: 10.55"

• Push Rod Diameter: 5/8"-18 UNF

• Chamber Height: 9.25"

• Mounting: 2 x Stud, 5/8"-11 UNC, 1.65" stud height

• Stud Spacing: Approx. 4.75"

• Ports: 3/8"-18 NPT (service and emergency)

• Construction: Corrosion-resistant steel with epoxy coating

• Fan/Seal: Sealed spring chamber design for environmental protection

• Compliance: Meets FMVSS-121 and SAE J1469 standards

• System Design: Dual-diaphragm for service and emergency brake operation

• Durability: OEM-grade reliability, high cycle life, designed for severe environments

• Technology: Internal contamination barriers to extend service life

• Compatibility: Fits multiple OE and aftermarket systems across North America

• Availability: Standard and long-stroke variants available (confirm part number)

Applications:

Built for drive and trailer axles on commercial trucks requiring 30/30 standard stroke spring brake chambers. Common across freight haulers, vocational trucks, and fleets needing sealed, weather-resistant emergency/parking brakes. Direct drop-in replacement for OEM chambers including Bendix, Haldex, and Mack part numbers.

CROSS-REFERENCE(S):

SB3030S2500, 3030S2500, S2500, 1010447, 1010449, 30/30, 3030STD, GC3030, LC3030, NT3030STD, S3030, S3030STD, 801386, 800386, E-11796, UP3030S2500, 179.SB3030S, NT3030STD78, 3431951, 3431951X, 3030TN2-2074, 165255, K049898, NT3030STD120, NT3030STD-120, 3030TS, GC3030P40, 19QE441RP1A cross-reference listing means this part may be a compatible replacement for these part numbers based on OEM or distributor data.

IMPORTANT INSTALLATION NOTES:

✔ Block wheels securely before removing brake chamber

✔ Depressurize air brake system prior to installation

✔ Use correct clamp band or stud mount based on axle type

✔ Torque mounting hardware to 35–40 ft-lbs unless OE specifies otherwise

✔ Ensure proper routing of service/emergency ports

✔ Set push rod length according to axle/brake specifications

✔ Leak test system after install and check for full chamber stroke

✔ Verify stroke type, mounting dimensions, and OE fitment before ordering

WHY CHOOSE FLEET PRODUCTS | KBR - HEAVY DUTY TRUCK & TRAILER PARTS?

• Canadian-owned since 1985• Trusted by fleets, mechanics, and B2B partners across North America

• Fast, Reliable Shipping Across North America

• Competitive pricing with Core Return Refunds

• Price Match Guarantee | Find a better price? We'll beat the difference by 10%!

Warranty Information

Reviews

1 Review

-

Straightforward install with proper adjustment flexibility

Installed this 30/30 spring brake on a drive axle replacement. The no-clevis design made a real difference, being able to set the push-rod length to match the existing slack adjuster avoided rework and stroke issues. Build quality is solid, ports and studs lined up correctly, and the chamber sealed up without leaks after installation. Parking and service brake operation are back within spec. Good option when you don’t want to fight fixed rod lengths.