Description

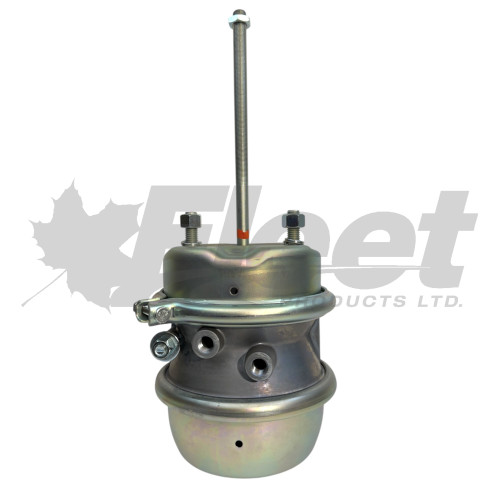

SB3030S2500 - 30/30 STD SPRING BRAKE

PART NUMBER(S):

Fleet Products: SB3030S2500 | OE: 1010447, 1010449, S2500 | Automann: 170.3030S2500

DESCRIPTION:

Model: 30/30 Standard Stroke Spring Brake Chamber

Vehicles: Freightliner, Kenworth T660, Peterbilt 379, Volvo VNL 670 Gen 2 (2003–2019), and other heavy-duty trucks/trailers

• Chamber Size: 30/30 (30 sq. in. service, 30 sq. in. emergency)

• Stroke: 2.5" standard stroke

• Push Rod Length: 10.55"

• Push Rod Diameter: 5/8"-18 UNF

• Chamber Height: 9.25"

• Mounting: 2 x Stud, 5/8"-11 UNC, 1.65" stud height

• Stud Spacing: Approx. 4.75"

• Ports: 3/8"-18 NPT (service and emergency)

• Construction: Corrosion-resistant steel with epoxy coating

• Fan/Seal: Sealed spring chamber design for environmental protection

• Compliance: Meets FMVSS-121 and SAE J1469 standards

• System Design: Dual-diaphragm for service and emergency brake operation

• Durability: OEM-grade reliability, high cycle life, designed for severe environments

• Technology: Internal contamination barriers to extend service life

• Compatibility: Fits multiple OE and aftermarket systems across North America

• Availability: Standard and long-stroke variants available (confirm part number)

Applications:

Built for drive and trailer axles on commercial trucks requiring 30/30 standard stroke spring brake chambers. Common across freight haulers, vocational trucks, and fleets needing sealed, weather-resistant emergency/parking brakes. Direct drop-in replacement for OEM chambers including Bendix, Haldex, and Mack part numbers.

CROSS-REFERENCE(S):

SB3030S2500, 3030S2500, S2500, 1010447, 1010449, 30/30, 3030STD, GC3030, LC3030, NT3030STD, S3030, S3030STD, 801386, 800386, E-11796, UP3030S2500, 179.SB3030S, NT3030STD78, 3431951, 3431951X, 3030TN2-2074, 165255, K049898, NT3030STD120, NT3030STD-120, 3030TS, GC3030P40, 19QE441RP1A cross-reference listing means this part may be a compatible replacement for these part numbers based on OEM or distributor data.

IMPORTANT INSTALLATION NOTES:

✔ Block wheels securely before removing brake chamber

✔ Depressurize air brake system prior to installation

✔ Use correct clamp band or stud mount based on axle type

✔ Torque mounting hardware to 35–40 ft-lbs unless OE specifies otherwise

✔ Ensure proper routing of service/emergency ports

✔ Set push rod length according to axle/brake specifications

✔ Leak test system after install and check for full chamber stroke

✔ Verify stroke type, mounting dimensions, and OE fitment before ordering

WHY CHOOSE FLEET PRODUCTS | KBR - HEAVY DUTY TRUCK & TRAILER PARTS?

• Canadian-owned since 1985• Trusted by fleets, mechanics, and B2B partners across North America

• Fast, Reliable Shipping Across North America

• Competitive pricing with Core Return Refunds

• Price Match Guarantee | Find a better price? We'll beat the difference by 10%!

Warranty Information