Core Return Freight Policy:

Core Return Freight Policy:

All core returns must be shipped freight prepaid if the shipment weighs 500 lbs or less.

For returns exceeding 500 lbs, we will arrange for collect freight using the courier of our choice. Please contact your sales representative for specific shipping instructions if your return qualifies for this option.

General Requirements:

Cores must have no major parts missing or damaged to obtain full core allowance.

Cores with damaged or missing parts are subject to reduced core allowances.

Cores may be returned against core charges up to 6 months after the date of purchase. Any returns beyond that will be treated as excess cores.

The following rules apply to all cores being returned:

- ⚠ All disassembled cores will be considered as having 2 parts damaged.

- ✖ Fire-damaged cores have no core value.

- ✖ Cores that have been welded, brazed, or repaired have no core value.

Fleet Products / KBR core acceptance is based on a simple visual inspection and 3 criteria:

- → The core must be an active part number currently offered for exchange.

- → The core must be in an off-engine condition, with no signs of prior rebuilding or damage due to fire, rust, or rough handling.

- → The core must meet the acceptance standards outlined below.

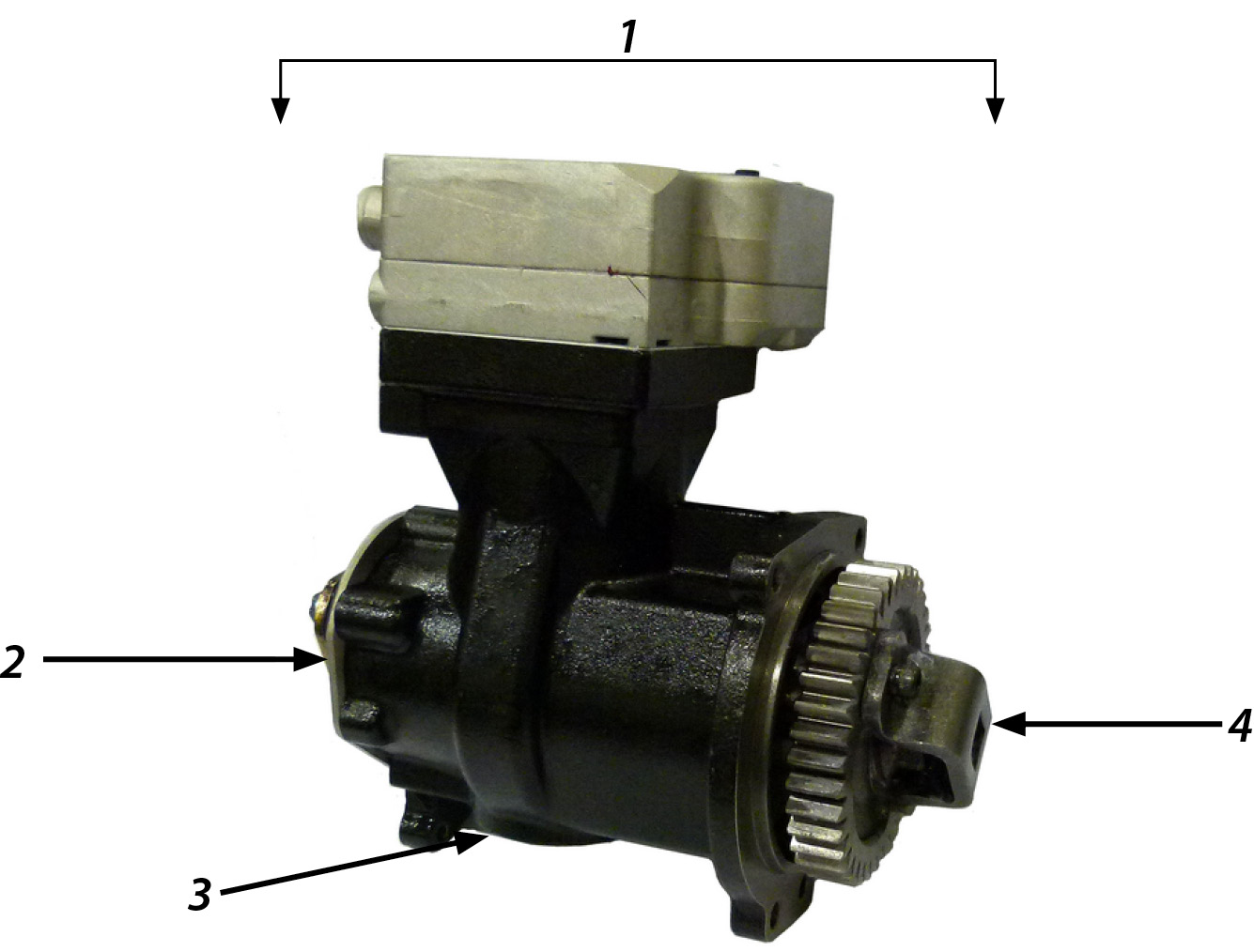

AIR COMPRESSORS

Core Acceptance Criteria

What to look for when inspecting your compressor core for return:

- → Crankshafts: Pulled or stripped threads, damaged key slots

- → Crankcases: Broken mounting flanges, cracked walls, broken base

- → Heads: Cracked water ports or damaged threads

- → Complete Units: Excessive corrosion/rust or fire/impact damage

Core Value Breakdown:

- ✔ Good Core: 100% Value

- ⚠ 1 Part Damaged: 50% Value

- ⚠ 2 Parts Damaged: 25% Value

- ✖ 3+ Parts Damaged: 0% Value

Examples of Damaged/Missing Parts:

- ⚠ 1 Part: Head, front cover, rear cover, gear, connecting rod, piston

- ⚠ 2 Parts: Broken crankshaft or crankcase, damaged flange/base

- ✖ No Core Value: Excessive corrosion/rust or fire/impact damage

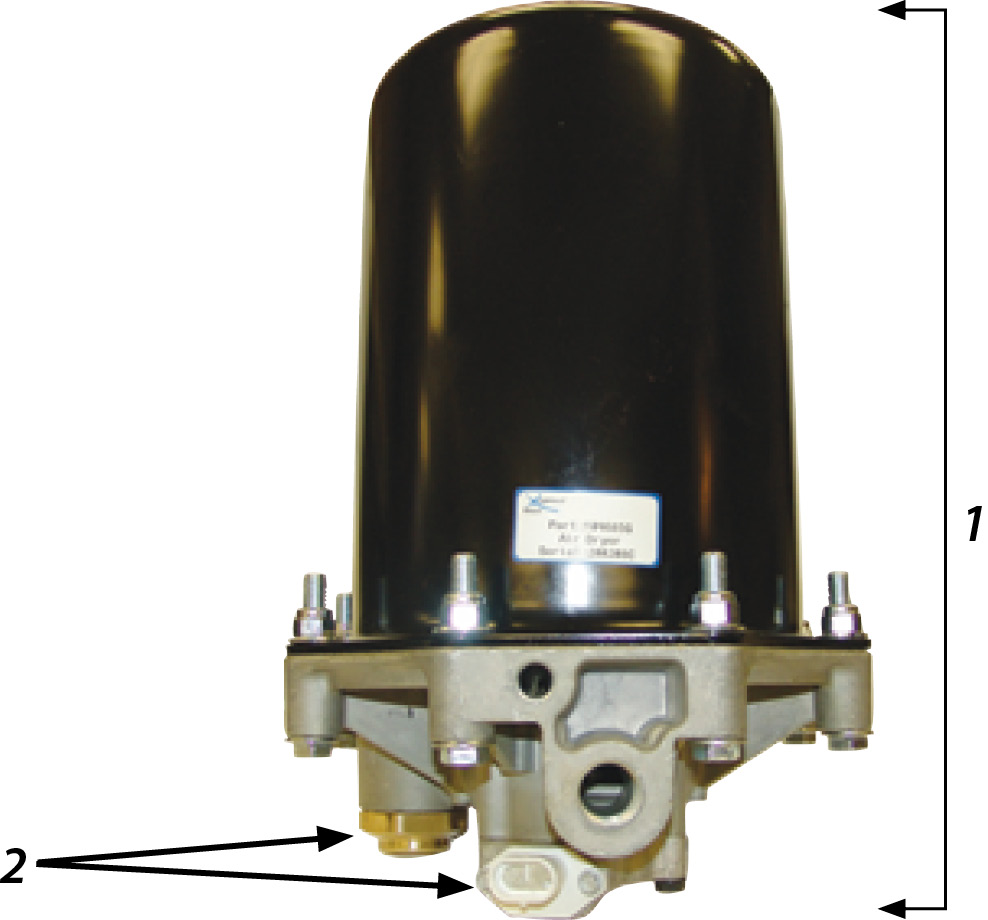

AIR DRYERS & DESICCANT CARTRIDGES

Core Acceptance Criteria

What to look for when inspecting your air dryer core for return:

- → Corroded or damaged can

- → Corroded cover

- → Missing components

- → Damaged or corroded lower body

What to look for when inspecting your desiccant core for return:

- → Broken or damaged bolt

- → Corroded or damaged can

Core Value Breakdown:

- ✔ Good Core: 100% Value

- ⚠ 1 Part Damaged: 50% Value

- ⚠ 2 Parts Damaged: 25% Value

Examples of Damaged/Missing Parts

- ⚠ 1 Part: Check valve or purge valve

- ⚠ 2 Parts: Missing both check/purge valves

- ✖ No Core Value: Broken bolt/stud, broken end cap, broken lid, broken or damaged housing, damaged threads, or excessive corrosion/rust

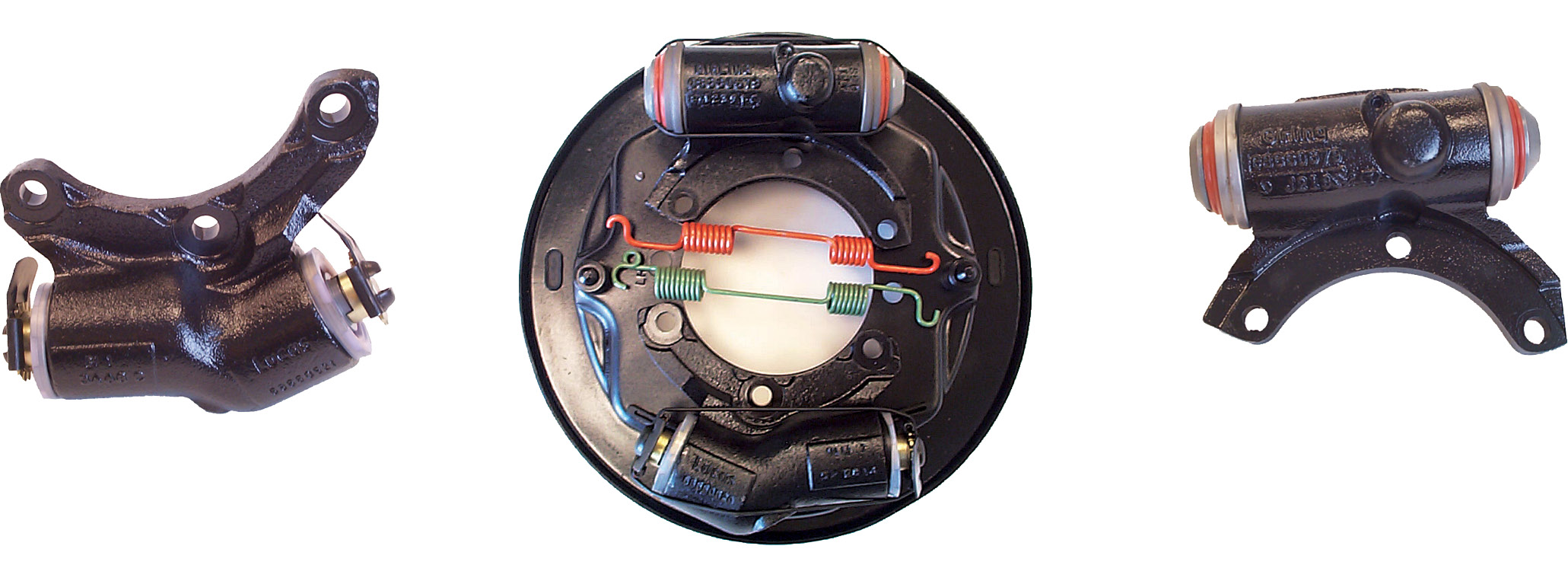

LUCAS PRODUCTS

Core Acceptance Criteria

What to look for when inspecting your Lucas cylinder core for return:

- → Missing or damaged components (pistons)

- → Damaged threads

- → Excessive corrosion/rust

What to look for when inspecting your Lucas backing plate core for return:

- → Missing or damaged components (missing cylinder or pistons)

- → Bent, damaged, or corroded assembly

- → Excessive corrosion/rust

Complete Backing Plates — Core Value Breakdown:

- ✔ Good Core: 100% Value

- ⚠ 1 Part Damaged: 50% Value

- ✖ 2 Parts Damaged: 0% Value

Examples of Damaged/Missing Parts

- ⚠ 1 Part Damaged: Missing piston, missing adjuster/expander cylinder, or bent/cut plate

- ✖ 2 Parts Damaged: Excessive corrosion/rust or two of the above issues present

Adjusting / Expander Cylinders — Core Value Breakdown:

- ✔ Good Core: 100% Value

- ✖ 1 Part Damaged: 0% Value

Examples of Damaged/Missing Parts

- ✖ 1 Part Damaged: Missing piston or damaged casting

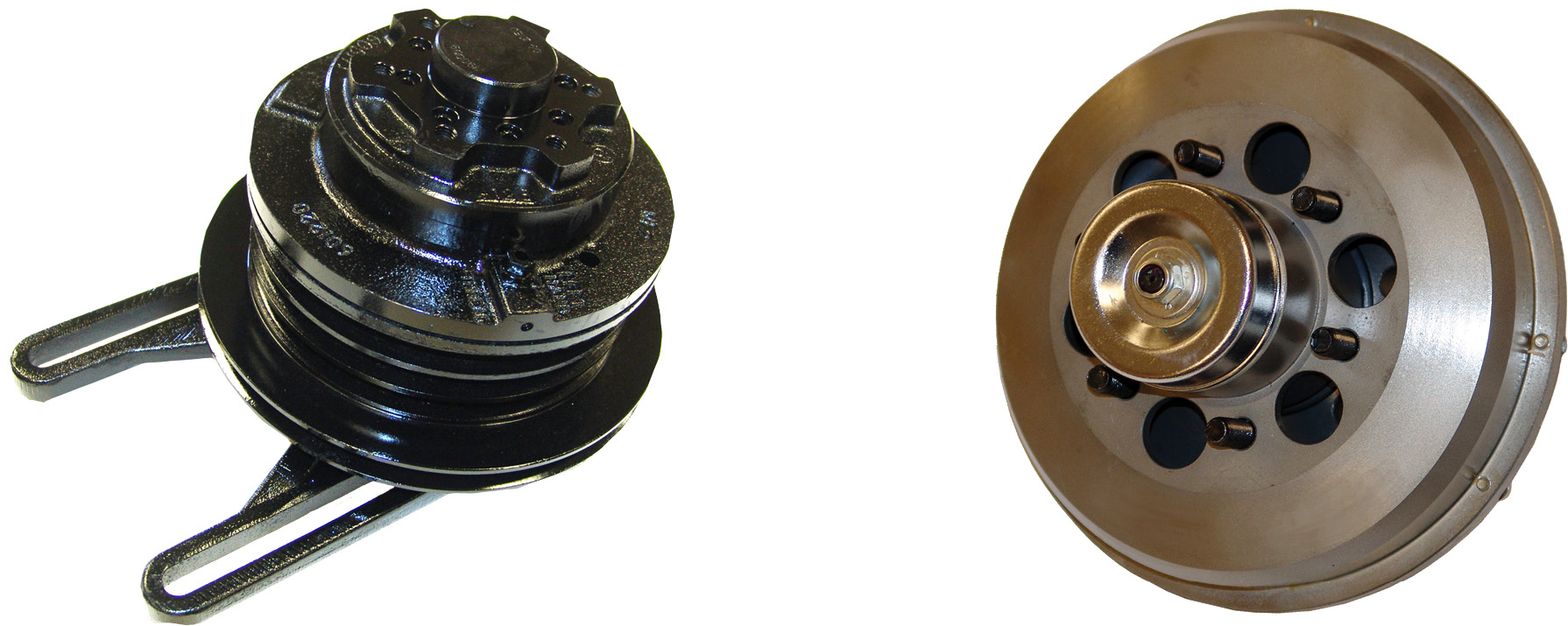

FAN CLUTCHES

Core Acceptance Criteria

What to look for when inspecting your Horton or Bendix fan clutch core for return:

- → Damaged pulley groove caused by rough handling

- → Seized bearings (this indicates a damaged shaft)

- → Damaged by non-operational causes (fire, rust, or rough handling)

What to look for when inspecting your Kysor fan clutch core for return:

- → Seized bearings (this indicates a damaged shaft)

- → Damaged by non-operational causes (fire, rust, or rough handling)

- → Excessive corrosion/rust

Core Value Breakdown:

- ✔ Good Core: 100% Value

- ⚠ 1 Part Damaged: 25% Value

- ✖ 2 Parts Damaged: 0% Value

Examples of Damaged/Missing Parts

- ⚠ 1 Part Damaged: Damaged pulley grooves, seized bearings, excessive corrosion/rust, or damaged shaft

- ✖ 2 Parts Damaged: When two or more of the above are applicable

HYDRAULIC COMPONENTS

Core Acceptance Criteria

What to look for when inspecting your Hydrovac core for return:

- → Disassembled or missing parts

- → Excessive corrosion/rust

- → Cracked or broken slave cylinder

What to look for when inspecting your Hydroboost / Electraboost core for return:

- → Disassembled or missing parts

- → Excessive corrosion/rust

- → Cracked or broken housing

What to look for when inspecting your Hydromax core for return:

- → Disassembled, missing parts, or damaged components

- → Damaged push rod or power piston shaft (shaft must be smooth and intact with no scratches, pitting, or dents)

- → Cracked or broken housing

Core Value Breakdown:

- ✔ Good Core: 100% Value

- ⚠ 1 Part Damaged: 50% Value

- ✖ 2 Parts Damaged: 0% Value

Examples of Damaged/Missing Parts

- ⚠ 1 Part Damaged: Missing components, cracked or broken housing/slave cylinder, damaged push rod/power piston shaft, or disassembled

- ✖ 2 Parts Damaged: Excessive corrosion/rust or disassembled

AIR DISC CALIPERS/CARRIERS

Core Acceptance Criteria

What to look for when inspecting your caliper core for return:

- → With the pads removed, use a screwdriver to depress the lever — it should rotate freely.

- → Pitted chamber counter-bore sealing surface

- → Missing cap, excessive corrosion/rust, or debris inside

- → Dents, dings, gouges, or impact marks

Core Value Breakdown:

- ✔ Good Core: 100% Value

- ⚠ 1 Part Damaged: 50% Value

- ⚠ 2 Parts Damaged: 25% Value

- ✖ 3 Parts Damaged: 0% Value

Examples of Damaged/Missing Parts

- ⚠ 1 Part Damaged: Missing cap, seized/broken lever, pitted sealing surface, excessive corrosion/rust, or debris inside

- ⚠ 2 Parts Damaged: Large dents, dings, gouges, or impact marks (6mm+)

- ✖ 3 Parts Damaged: Any condition that makes the caliper inoperable or beyond repair